Saphite represents the future of crystalline materials. It is a polycrystalline glassy ceramic material formed by crystallising crafted elements and a base glass. Compared to traditional materials, this material offers improved physical and chemical properties.

Saphite has been created to allow the production of an array of colours while maintaining an industry-leading level of clarity and brilliance.

What is Saphite™?

Saphite is a multi-component high-temperature composition formed by two main oxides – SiO2 and Al2O3. It is well-known that the above-mentioned oxides are key components of most natural gemstones.

The rest of Saphite’s components are selected in order to determine the colour of the material. Our technology allows us to vary components of composition quite widely while retaining the same level of clarity.

More impact resistant /

The unique structure of saphite™ provides an improved impact resistance.

More colours /

The most significant difference between sapphire crystal and Saphite™ is its incredible colour possibilities. Capable of producing a huge array of colours without losing any clarity or brilliance.

More brilliant /

Due to Saphite™’s lower refractive index at 1.65 than sapphire at 1.76, light passes through it more quickly, causing it to glow brilliantly.

More impact resistant /

The unique structure of saphite™ provides an improved impact resistance.

More colours /

The most significant difference between sapphire crystal and Saphite™ is its incredible colour possibilities. Capable of producing a huge array of colours without losing any clarity or brilliance.

More brilliant /

Due to Saphite™’s lower refractive index at 1.65 than sapphire at 1.76, light passes through it more quickly, causing it to glow brilliantly.

The new industry standard /

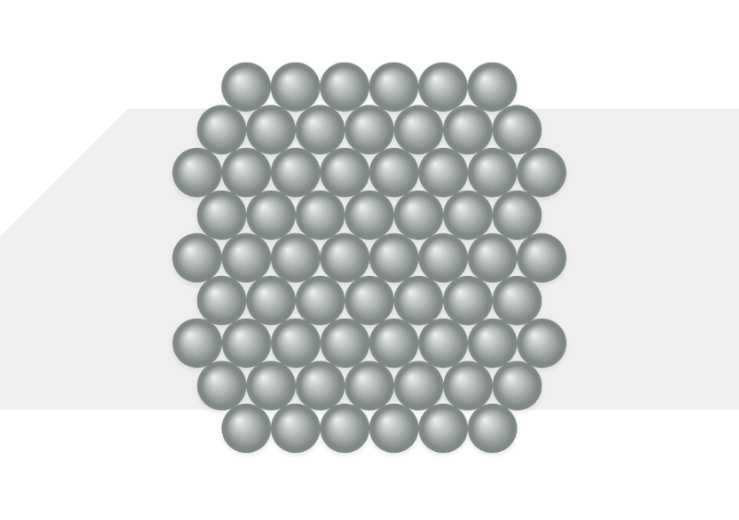

Crystalline

Sapphire crystal is the current industry standard of crystalline material used in jewellery and watchmaking. A synthetic material derived from crystallisation of pure aluminium oxide. Sapphire crystal has proved to be very durable, with a Moh’s scale hardness of 9/10.

But in this, hardness lays its weakness. Sapphire crystal is prone to shattering on impact and, due to the rigidity of its crystalline structure, can only be produced in a very limited array of colours.

In contrast to sapphire crystal, Saphite™ is a polycrystalline glass ceramic.

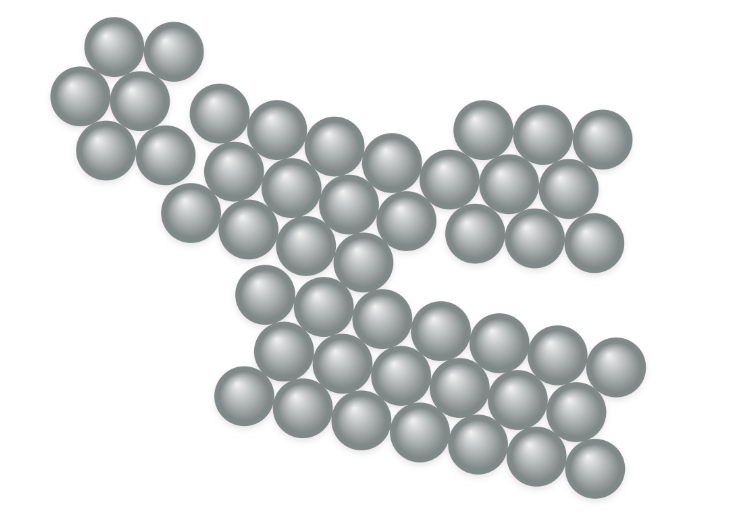

polyCrystalline

This unique structure means that unlike the rigid formation of sapphire crystal, Saphite™ is formed through the fine uniform dispersion of crystal through a bulk material.

This structure provides SaphiteTM with improved clarity and brilliance due to lights’ ability to bounce between these suspended fine crystal structures. Further, Saphite™ has better shatter and impact resistance since, unlike sapphire crystal, the material’s strength does not hinge on the tight structure but on the bulk material’s strength.

Glass Ceramics /

Glass Ceramics /

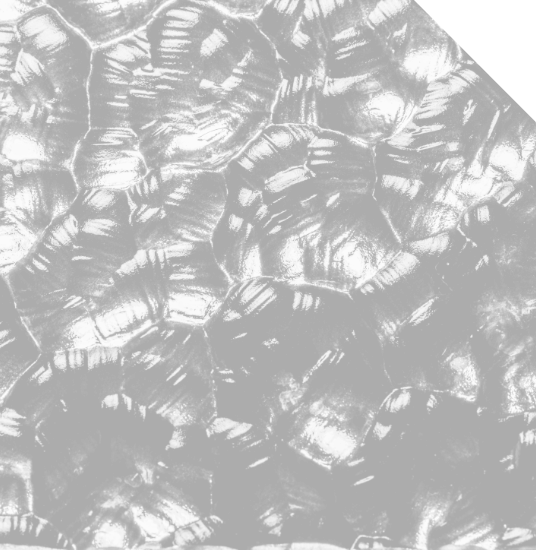

Generally, glass-ceramics are polycrystalline materials that are formed by the controlled crystallisation of base glass, which produces a fine uniform dispersion of crystals throughout the bulk material.

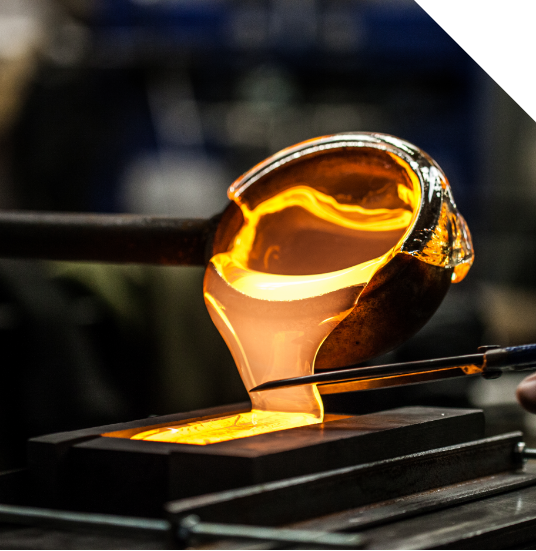

In order to crystallise, suitable glasses are treated carefully with heat in order to initiate and grow crystal phases. Crystallisation can often proceed to near completion, but in a small percentage of cases, a residual glass phase remains.

Glass-ceramic materials share numerous properties with both glass and ceramics. Unlike spontaneous crystallisation, which is usually not desired in glass manufacture, glass ceramics have two phases: amorphous and crystalline.

A glass-ceramic combines the fabrication advantages of each phase to create a brand new material.

A glass ceramic typically has a crystallinity of 30% to 90% and can produce an array of materials with interesting properties.

Including the following.

— Zero porosity

— High strength

— Toughness

— Translucency or opacity

— Pigmentation

— Opalescence

— Low or even negative

thermal expansion

— High-temperature

stability

— Fluorescence

— Machinability

— Ferromagnetism

— Resorbability or high

chemical durability

— Biocompatibility

— Bioactivity

— Ion conductivity

— Superconductivity

— Isolation Capabilities

— Low dielectric constant

and loss

— Corrosion resistance

— High resistivity and

break-down voltage.

By controlling the composition of the base glass and by controlling the heat treatment/crystallisation of the base glass, these properties can be tailored.

Glass Ceramics /

Generally, glass-ceramics are polycrystalline materials that are formed by the controlled crystallisation of base glass, which produces a fine uniform dispersion of crystals throughout the bulk material.

In order to crystallise, suitable glasses are treated carefully with heat in order to initiate and grow crystal phases. Crystallisation can often proceed to near completion, but in a small percentage of cases, a residual glass phase remains.

Glass-ceramic materials share numerous properties with both glass and ceramics. Unlike spontaneous crystallisation, which is usually not desired in glass manufacture, glass ceramics have two phases: amorphous and crystalline.

A glass-ceramic combines the fabrication advantages of each phase to create a brand new material.

A glass ceramic typically has a crystallinity of 30% to 90% and can produce an array of materials with interesting properties.

Including the following.

— Zero porosity

— High strength

— Toughness

— Translucency or opacity

— Pigmentation

— Opalescence

— Low or even negative

thermal expansion

— High-temperature

stability

— Fluorescence

— Machinability

— Ferromagnetism

— Resorbability or high

chemical durability

— Biocompatibility

— Bioactivity

— Ion conductivity

— Superconductivity

— Isolation Capabilities

— Low dielectric constant

and loss

— Corrosion resistance

— High resistivity and

break-down voltage.

By controlling the composition of the base glass and by controlling the heat treatment/crystallisation of the base glass, these properties can be tailored.

Contact us /

Currently the application of SaphiteTM is available by invitation only. If you are interested in working with SaphiteTM, please complete the contact form below.